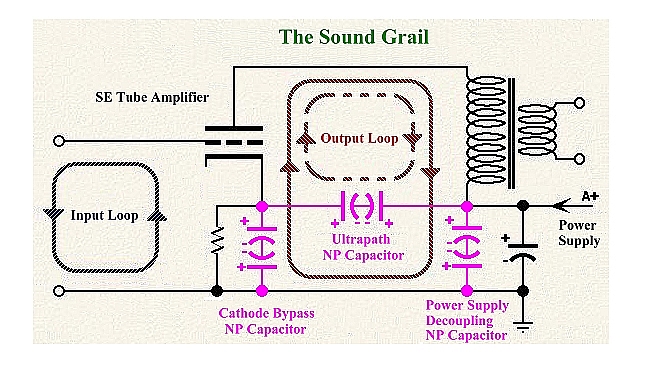

The audio signal path in a single-ended amplifier

Any single ended valve amplifier, like this, is highly sensitive to the quality of the power supply and of the employed capacitors. In fact the signal current, like any other, has to flow in a loop and, normally, whichever signal current flows across the cathode and the plate of the tube and the output transformer must complete a loop through the power rail decoupling capacitors and the cathode bypass capacitor (red output loop).

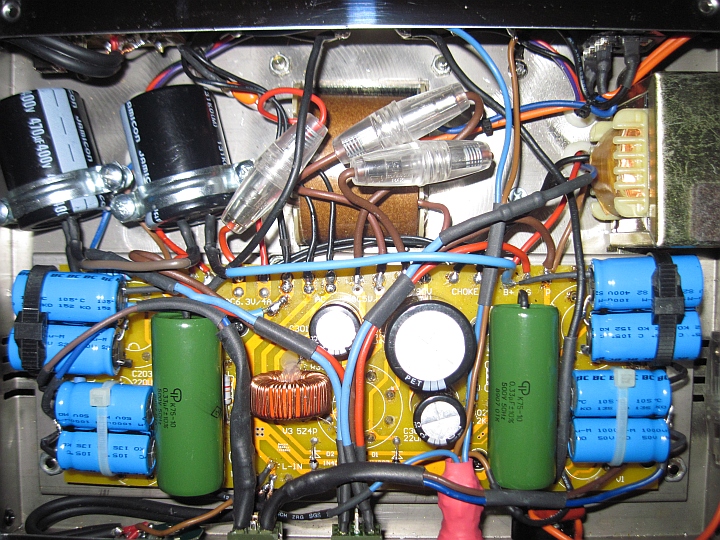

In particular, in The Sound Grail amplifier, an Ultrapath™ topology is employed. An additional capacitor connected as a bridge between the cathode of the tube and the A+ positive power rail keeps a portion of the signal current in a separate loop (red dasched output loop) which is shorter and away from both the power supply impedance and the cathode bypass capacitor. The main goal of this configuration is hum noise cancellation. This ultrapath capacitor is usually sized "mu-1" times smaller than the bypass capacitor (for KT77 the amplification factor mu is 11.5, thus the ultrapath capacitor is about one-tenth of the cathode one): the capacitive reactance of these two capacitors forms a 1:10 AC voltage divider, so a part of the power supply variations are injected at the cathode, which helps to reduce the power supply noise.

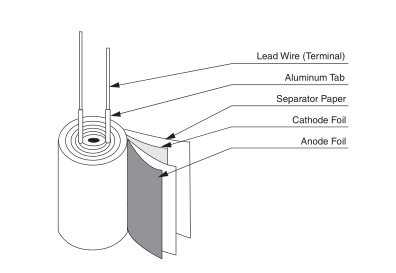

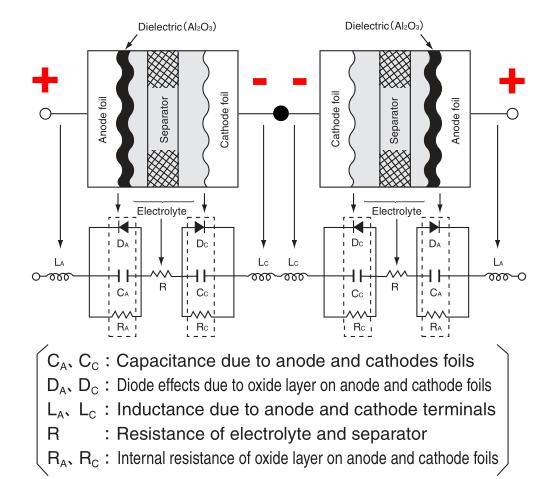

Where the signal current passes through a capacitor, the quality of this capacitor becomes very important: as far as why certain capacitors sound different than others, that becomes a hard question to answer and measure.